"With a global presence and engineering excellence, we ensure every project is executed with precision-anytime, anywhere."

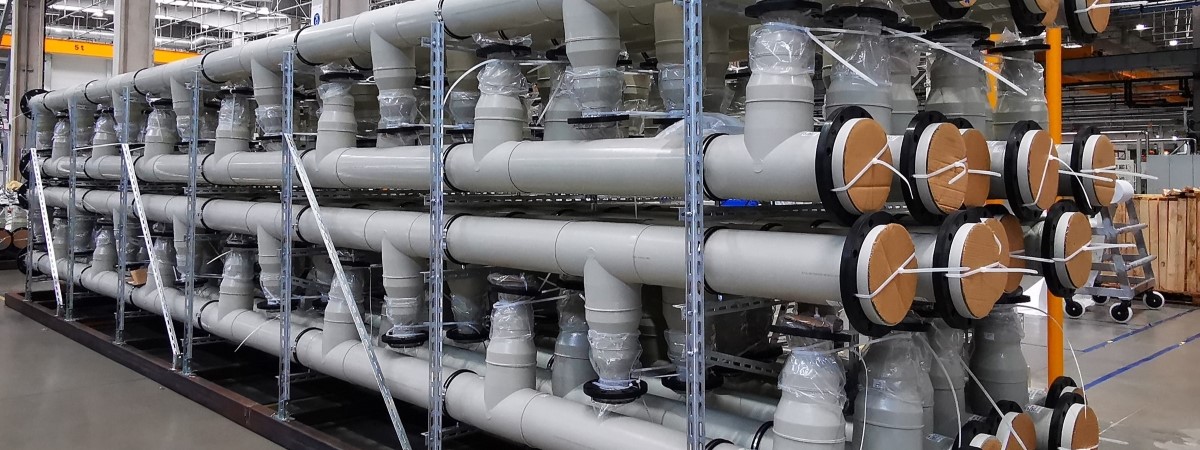

As industrial projects grow in scale and complexity, companies face tight deadlines, increasing regulatory demands, complicated logistics scenarios, and complete traceability of installed components.

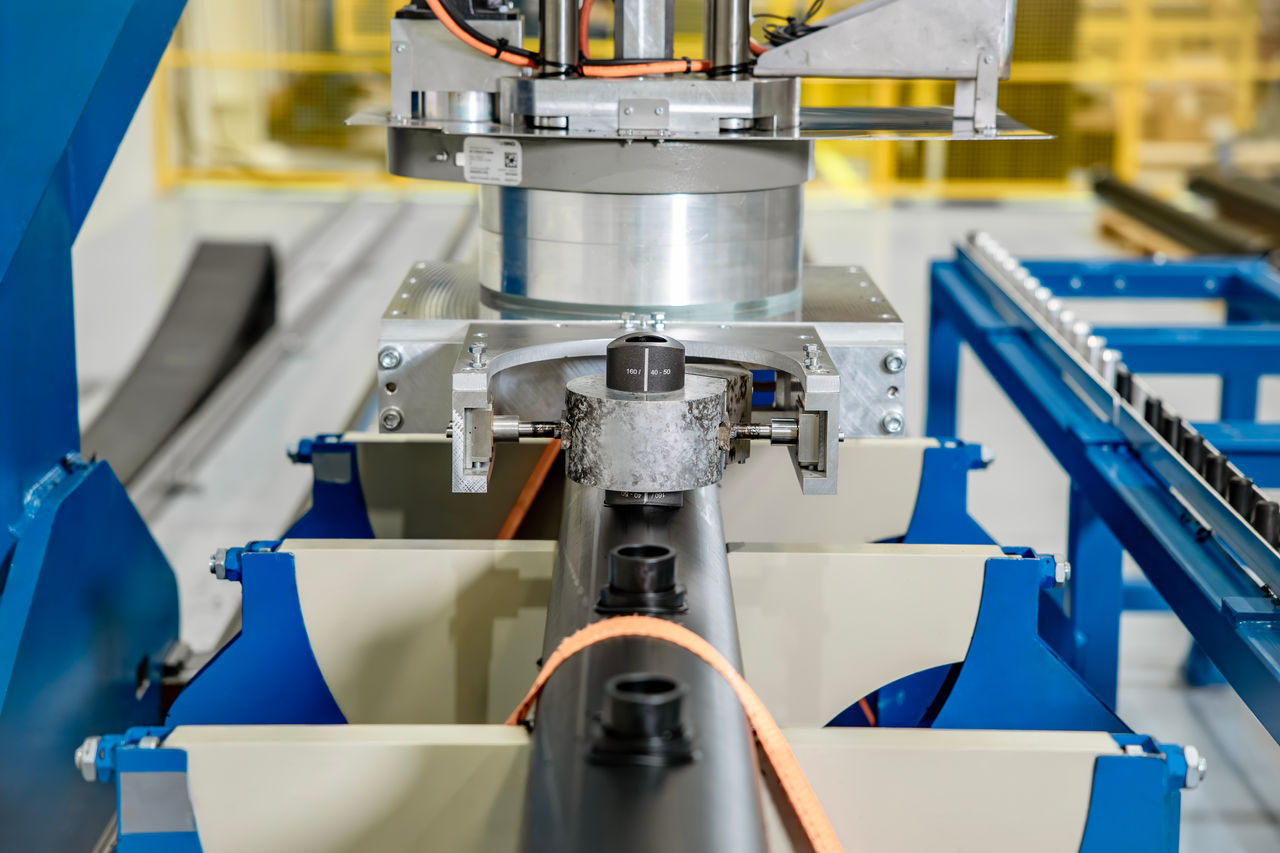

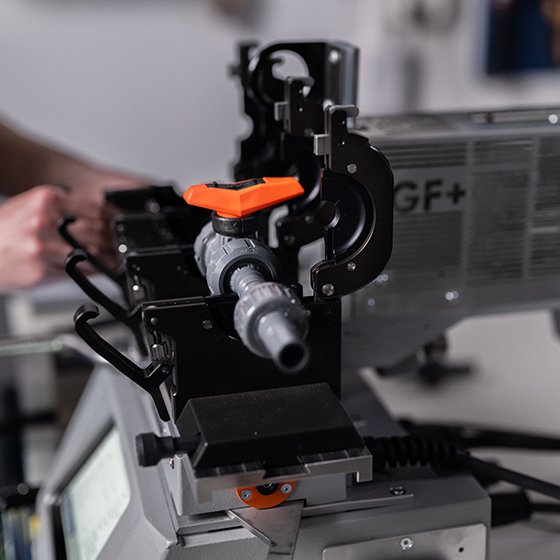

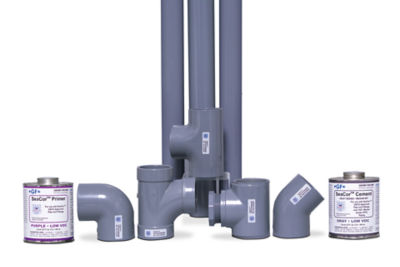

Our integrated approach minimizes project risks and ensures traceability across all components. We are committed to simplifying your journey. At GF we manage the entire supply chain process from raw materials to final pre-fabricated components, passing by the operation of extrusion and injection molding factories and dozens of GF-owned pre-fabrication facilities across the globe. All while optimizing logistics for our customers as efficiently as possible.