Engineered for chemical resistance, reliability, and compliance

In semiconductor manufacturing and industrial wastewater treatment, fluid handling systems must safely manage a wide range of aggressive and hazardous media. These include mineral and organic acids, alkalis, oxidizing agents, metal-laden solutions, solvents like isopropyl alcohol (IPA), as well as fine particulates and suspended solids. Contamination-free conveyance is critical, not only to protect downstream treatment technologies such as neutralization, filtration, and reclaim systems but also to ensure environmental compliance, enable material recovery, and minimize operational risk. Any leakage or material degradation could compromise worker safety, equipment performance, or discharge quality.

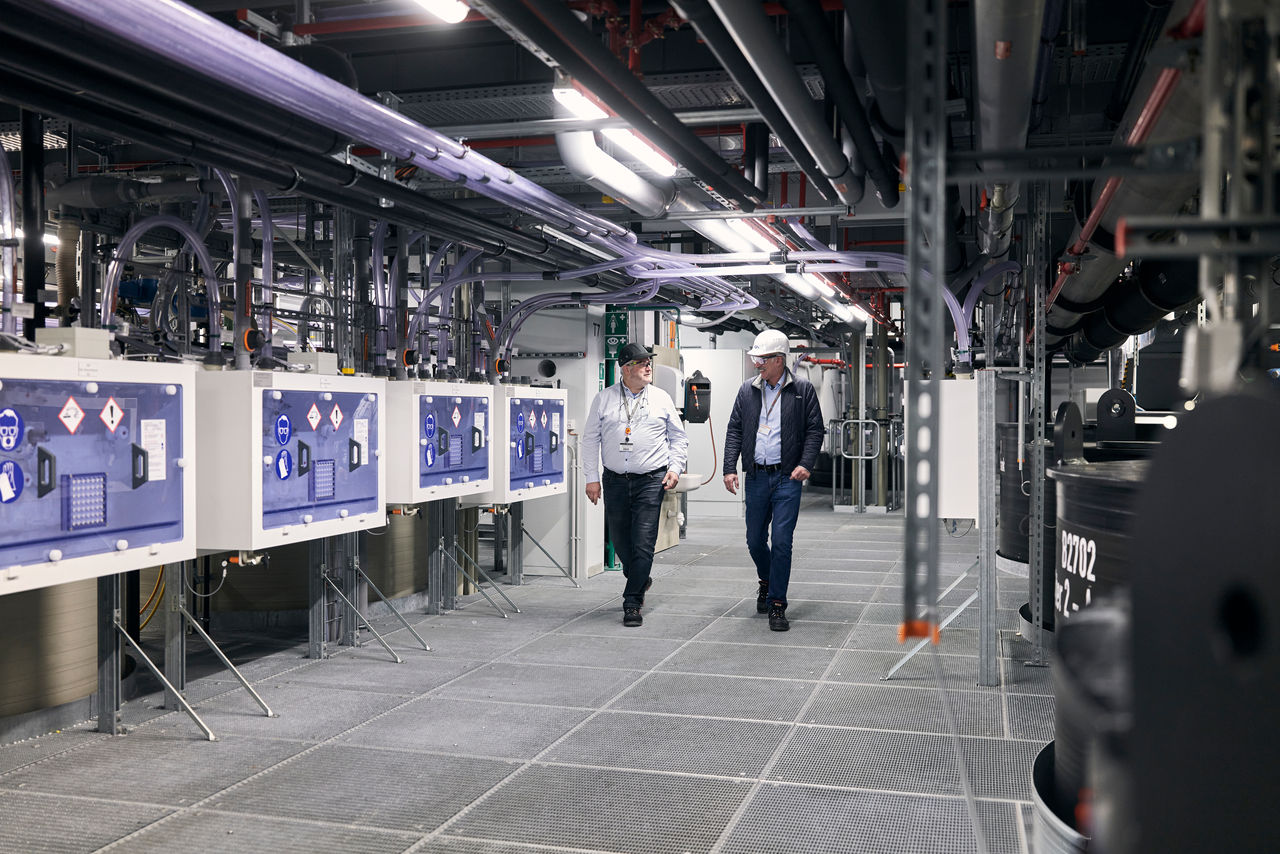

GF Industry and Infrastructure Flow Solutions offers fully engineered polymer piping solutions for safe, contamination-free transport and integration of hazardous media. Designed for durability, chemical resistance, and system compatibility, our solutions ensure long-term performance under corrosive and fluctuating process conditions, helping engineers meet environmental, operational, and regulatory targets.