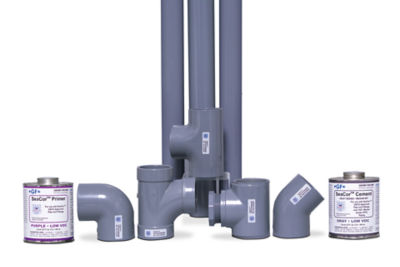

The integrity of a piping system is essential during the operation of any piping application. GF’s specialists can check new welds with Ultrasonic NDT or inspect samples of applications running for years in our accredited material testing laboratory, providing valuable insight for Operators’ decision-making.

Ultrasonic NDT & Pipe Condition Assessment

We offer two systems that deliver steadfast data about the status of your system, based on science, giving you peace of mind for your operation at all times: