Critical Cooling

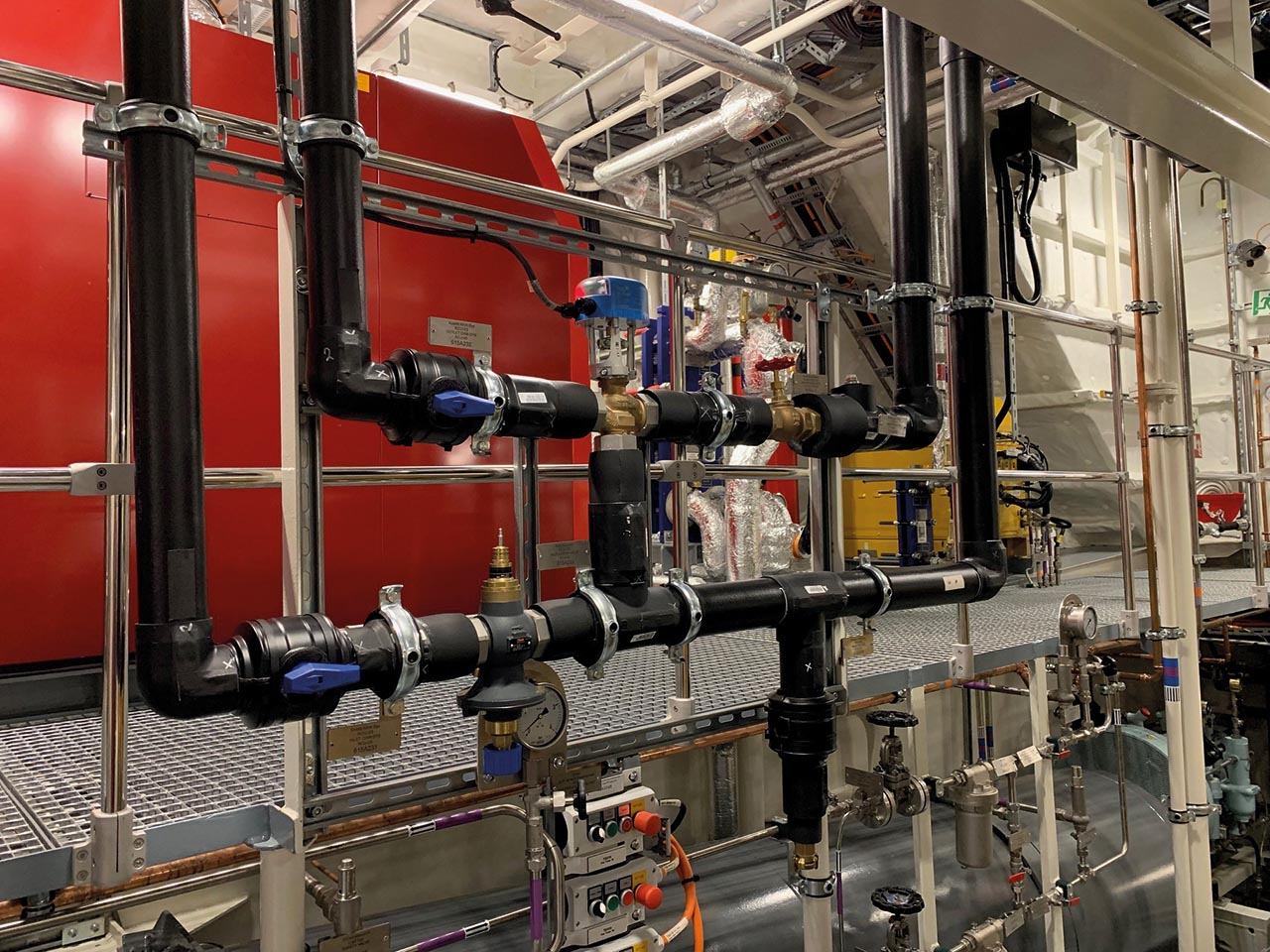

Cooling plays a critical role in maintaining the day-to-day work of many industries, for example, by cooling the machines used in manufacturing or reducing the heat produced from industrial processes, protecting the machines and facilities from overheating and supporting their safe and continuous operations. In addition, cooling provides relief for people during hot weather months, and supports global food security by preserving food at the right temperature through the stages of production, transportation, and consumption, extending its shelf life.