The Future of Sustainable Aquaculture

Aquaculture is rapidly evolving to meet the growing demand for sustainable food production, especially as more than 35% of the world's marine stocks are already overfished. Traditional net-pen farms face rising costs and regulatory challenges, making alternatives essential. There is a need for a more efficient, sustainable, and technologically advanced aquaculture.

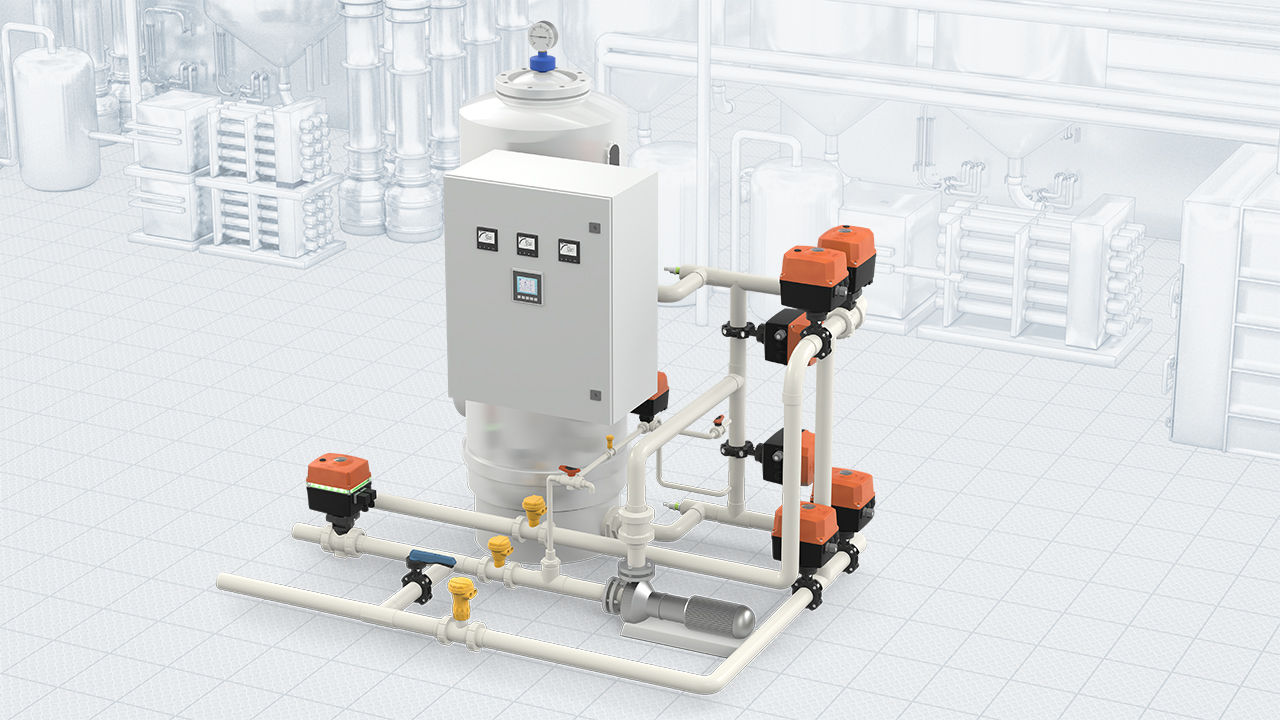

Controlled environment farming is rapidly becoming the industry standard. Key technologies like recirculating aquaculture systems (RAS) and hybrid flow-through methods reduce water usage and waste, allowing for flexible land-based farming near market locations. Additionally, there is a growing emphasis on animal wellbeing, with advanced sensors and automation maintaining optimal water quality and environment health monitoring.