Maintaining drinking water hygiene in any building is a challenge. Cold water from the urban water system enters the building and flows through a complex network of small dimension pipes over a long period at elevated temperatures. These conditions pose a risk for the proliferation of germs (Legionella bacteria) and may adversely affect human health.

Legionella in drinking water

The number of Legionnaires' disease cases being recorded worldwide is on the rise. The World Health Organization (WHO) classifies Legionella as the bacteria with the greatest impact on health among all waterborne pathogens.

What are Legionella?

Legionella are bacteria that are found in environmental sources all over the world. They occur in nature, for example in surface water or groundwater. Legionella can be present in drinking water in low concentrations. When conditions are favorable for Legionella, they multiply exponentially and can become a danger to human beings above a certain concentration.

Although there are different species of Legionella, "Legionella pneumophila, serogroup 1" is the cause of over 90% of all severe Legionella infections.

What danger do Legionella pose?

Legionella is a pathogenic bacteria, meaning it can cause illness in humans. The infection occurs when inhaling water droplets (aerosols) containing Legionella, including when showering. Legionella can cause severe pneumonia (Legionnaires' disease), which can be fatal to people with compromised immune systems. Pontiac fever is less dangerous than Legionnaires' disease. It manifests with flu-like symptoms, and usually subsides after a few days.

How serious is the risk of Legionella in buildings?

In principle, Legionella concentrations in the drinking water supply system are fairly small due to the low temperatures. That said, drinking water in buildings is heated up (cold and hot water) and sometimes remains in place for prolonged periods of time. Under these conditions, Legionellae can multiply rapidly (exponential growth) and reach concentrations that can affect hygiene.

Principles of drinking water hygiene in buildings

There are various factors involved in ensuring sustainable drinking water hygiene and preventing the proliferation of Legionella.

How can all this be achieved in the design and construction of a building?

Use of hygienically compliant materials

Contact between materials and drinking water can cause substances to migrate. This can result in a change in the drinking water's taste or odor, a chemical change and also a microbial change (if the substances act as nutrients for microorganisms).

All materials, pipes, piping components, fittings and appliances used in drinking water installations, as well as any equipment required, must therefore comply with the nationally applicable statutory hygiene requirements. It is recommended that certified products meeting internationally valid standards are used.

Minimizing corrosion is essential to sustainable drinking water hygiene, as corroded surfaces provide niches for microorganisms to colonize, and corrosion products can lead to the formation of deposits that alter the hydraulic mechanisms. In addition, corrosion-resistant materials prevent the abrasion of microplastics when a drinking water installation is in operation.

Valves & piping systems from GF:

- are compliant with hygiene requirements

- are extremely durable thanks to their high-grade materials

Observing standards and regulations

Drinking water installations can be operated safely and hygienically throughout their service life if the standards and regulations for planning, construction and operation are observed.

These regulations define the state of the art, ensure both safety and comfort, and protect against the consequences of a drinking water installation contaminated by microbes.

Dimensioning to meet requirements

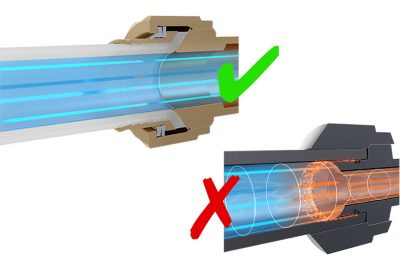

The piping system and the hot water tank must be rated for the use concerned. With oversized pipes, there is a risk that only a laminar flow occurs in the center of the pipe and water is not exchanged at the pipe walls.

Piping systems with a full pipe cross-section, such as JRG Sanipex, JRG Sanipex MT und INSTAFLEX allow the smallest possible dimensions to be used. This minimizes the amount of water in the drinking water installation, meaning that the volume in the pipes can be exchanged in a faster time.

Our Experts will be happy to assist with the pipe dimensioning process for your project.

Avoiding water pockets

We recommend the use of a piping system featuring connection technology and fittings without any water pockets, because drinking water stagnates in these spaces. They encourage the formation of biofilm in which pathogenic bacteria such as Legionellae can multiply.

The GF Piping Systems cone grip union connection technology available in the JRG Sanipex and JRG Sanipex MT piping systems has been scientifically tested by the Fraunhofer Institute to ensure that all connections meet the sterility criteria. The water pocket-free, full pipe cross-section offers further advantages, including minimal flow noise and virtually no pressure losses.

JRG valves, too, are designed without water pockets. They are made of high-grade materials that meet the highest hygiene requirements.

Dead legs, such as tapping points, which are no longer used or are not used as intended, also present a problem. Since they are no longer involved in the flow of water through the system, they need to be decommissioned and dismantled. Microbial growth that can occur in dead pipes also contaminates the main line against the direction of flow.

Minimizing corrosion

Corrosion residues provide an ideal breeding ground for Legionellae. This is why corrosion-resistant materials are preferable when planning a drinking water installation. Plastic pipe systems are considered to be especially resistant to corrosion.

Our plastic piping systems for drinking water installations:

High-grade gunmetal and stainless steel components ensure the corrosion resistance of our JRG valves.

Cleanliness when working

Hygienically impeccable storage and processing are fundamental to a safe drinking water installation. When a drinking water system is installed, contamination may occur if products are stored or handled incorrectly. Contaminants on surfaces that come in contact with water can be an excellent source of nutrients for microorganisms. To prevent contamination, these surfaces should be protected by suitable packaging. In addition, all tools used must be kept clean at all times.

GF products for drinking water installation have:

- hygienic packaging

- the most sustainable packaging design and materials possible

Hydraulic balancing

A drinking water system with central hot water generation must be hydraulically balanced to ensure that the hot water temperature of 55°C required for hygiene reasons is not undershot at any point in the installation. To reduce the manual effort of hydraulic balancing, GF Piping Systems has developed the Hycleen Automation System.

The Hycleen Automation System continuously manages and controls the process of hydraulic balancing in a highly efficient way. The end-to-end solution combines sensors and digitized valves connected to a central master unit. The master automatically controls and optimizes the hydraulic balancing process on a daily basis.

Hydraulic balancing with the Hycleen Automation System

- Ensuring permanent temperature-based hydraulic balancing

- Proven compliance with normative requirements through documentation

- Regular functional test and cleaning of the circulation valves

- Central operation via the Hycleen Master or via cloud-based remote access

Please accept all cookies to view the youtube video content.

Hygienic flushing

The longer the water remains in the drinking water installation (stagnation), the greater the risk that any Legionellae and other microorganisms it contains will multiply. The water in the hot and cold water pipes must therefore be exchanged throughout the drinking water installation on a regular basis in order to counteract high bacterial concentrations over the long term. If regular use is not possible, e.g. in hotels or sports complexes, automatic flushing can ensure drinking water hygiene.

The Hycleen Automation System enables automatic flushing of cold and hot water pipes based on temperature, time or consumption. Each flushing process is recorded and logged.

Hygiene flushing with the Hycleen Automation System

- Demand-based water exchange based on effective water consumption

- Flushing when hygiene-critical temperatures are reached or after defined time intervals

- Documentation of each flushing sequence

- Central operation via the Hycleen Master or via cloud-based remote access

Avoiding limescale deposits and incrustations

Limescale deposits and incrustations in pipelines and hot water tanks encourage microorganisms to settle permanently and proliferate out of control. This is because faultless operation of the system can no longer be ensured due to the deposits. In addition, a layer of limescale in the heat generator hinders thermal transfer to the drinking water, considerably reducing energy efficiency in the process. In the worst case, this can also lead to hygienically precarious temperatures.

Preventive limescale protection is therefore important for drinking water containing limescale, not only because of the technical advantages (energy efficiency), but also to ensure drinking water hygiene.

How can drinking water hygiene be ensured in the long term?

Regular condition check

During operation, the installation has to be checked on a regular basis to ensure faultless functionality. The operator of a drinking water installation is responsible for making sure this happens.

If an installation is not used for its original purpose (intended operation in accordance with standards & regulations), a specialist firm must be engaged to adapt the drinking water system to the changed conditions. Contact us for more information, our experts will be happy to assist you.

Rigorous maintenance

To maintain operational safety, all appliances like water heaters, pipe and extraction fittings must be inspected and maintained on a regular basis. This is how deficiencies can be ruled out and hazards avoided.

Legionella sampling

To ensure impeccable drinking water quality, samples should be – or rather must be – taken at regular intervals, depending on the type of building. A specialist must take the samples from meaningful points in accordance with the applicable regulations. A Legionella analysis is then conducted in an accredited laboratory. Sampling valves are required to ensure proper sampling.

Sampling valves should be designed in such a way that they can be disinfected/flame-sterilized and so that no aerosols form as water is being extracted.

Intervention through disinfection

If the applicable Legionella limit values or other pathogens are found to be exceeded when drinking water is sampled, this is usually due to neglect of preventative measures. Any intervention should be kept to a minimum and only used as a last resort. This is where the options for thermal or chemical disinfection come into play. For successful and sustainable disinfection, it is necessary to know exactly the cause and location of the contamination. In addition, the implementation should be carried out in accordance with the local applicable guidelines.