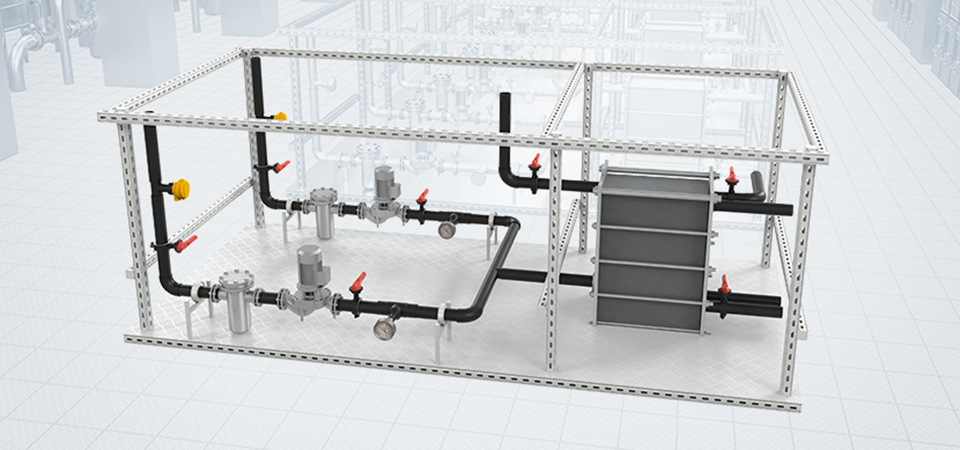

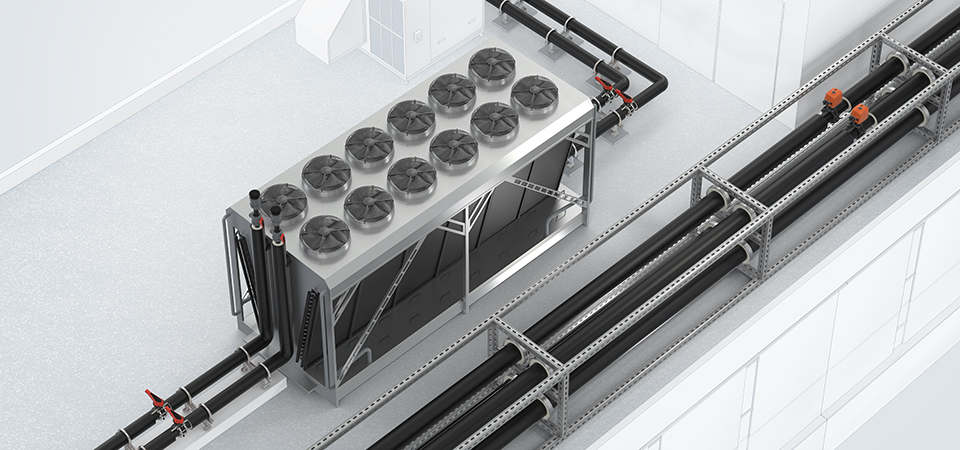

From chiller to chip: engineered flow solutions for a complete cooling infrastructure

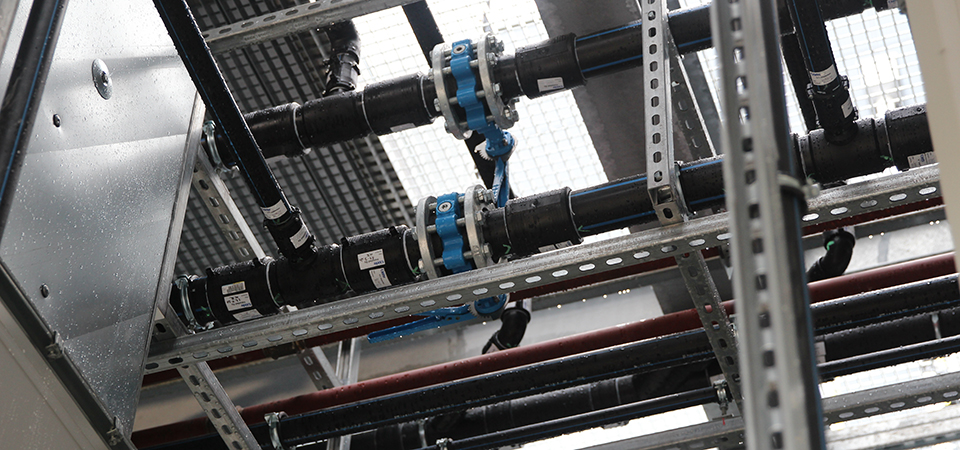

At GF Industry and Infrastructure Flow Solutions, we specialize in mission-critical flow solutions that ensure safe, efficient, and scalable cooling performance across your entire Data Center infrastructure, from Condenser Water Systems (CWS) to Facility Water Systems (FWS) to Technology Cooling Systems (TCS), supporting advanced Direct Liquid Cooling (DLC) systems. With over 30 years of experience in high-purity semiconductor manufacturing and as a Silver Member of the Open Compute Project (OCP), we develop innovative solutions to meet the industry's highest expectations in cooling performance, uptime, and energy efficiency.