Multilayer pipes in combination with the clamp connection technology

What makes JRG Sanipex MT unique? The multilayer pipes and fittings are produced in the two-layer injection moulding process combined with the ingenious flared clamp connection technology. Combined with many other benefits this makes the holistic system ideal for distribution, riser, and connection lines in single-family homes and large-scale projects for drinking water, heating, cooling, or compressed air.

Please accept all cookies to view the youtube video content.

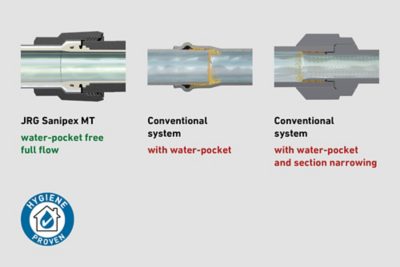

Hygienically perfect pipe connections

JRG Sanipex MT - the holistic system for hygienically perfect pipe connections. For 20 years, the system continues to provide:

- Full pipe cross-section without dead spaces and only with minimal pressure losses

- Detachable and reusable connection from d12 - d63

- Corrosion and limescale resistant plastic technology

- Noise-less flow owing to the full pipe cross-section

- NEW: Fitting insulation shells

- NEW: additional PE-RT pipes

Installation videos

Watch our videos to learn how to install JRG Sanipex MT easily and quickly.

Please accept all cookies to view the youtube video content.

Good for you - certified for the environment

Did you know? JRG Sanipex MT is made of environmentally friendly and recyclable materials, which is why the pipe system is certified according to BREEAM, LEED, and DGNB.

BREEAM DGNB

BREEAM DGNB