COOLnews Topics

Welcome to the COOLnews landing page featuring helpful resources each quarter to help make your cooling loop or any other cooling requirements the most efficient yet.

Metal piping systems come with a long list of challenges in chilled water, glycol and brine applications:

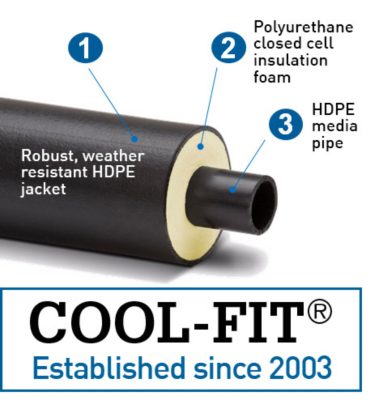

It's time for a change: a unique 3-in-1 pre-insulated plastic piping system that is easy and fast to install, safe, reliable and environmental friendly.

Welcome to the COOLnews landing page featuring helpful resources each quarter to help make your cooling loop or any other cooling requirements the most efficient yet.

Save time and money on installation. Read more below and watch our comparison video of an identical metal pipe installation versus pre-insulated plastic piping system, the result is impressive!

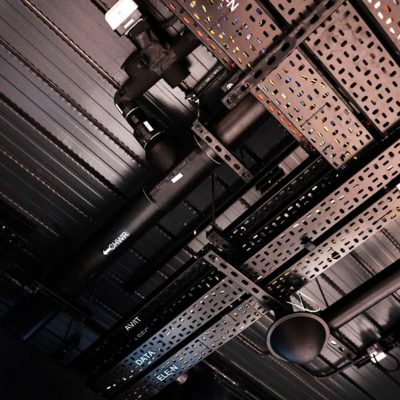

Pre-insulated plastic piping systems are perfectly sealed cooling circuits and prevent energy loss, having a huge impact on costs and your plant's energy consumption.

Reliable and robust pre-insulated plastic piping systems are 100% maintenance free and corrosion free preventing condensation as well as ice build up.

The closed cell insulation is fully bonded to both the media pipe and the robust external jacket. Continue reading below for more information.

Please accept all cookies to view the external content.

Efficient, reliable and sustainable cooling loops are necessary in a variety of industries and applications.

gfps-au-cold-store.jpg

gfps-au-cold-store.jpg

Future horizons of cruiseships: GF Piping Systems at SMM

Future horizons of cruiseships: GF Piping Systems at SMM

Improving Energy Efficiency

Improving Energy Efficiency