With our Flow Calculator, you can easily determine key parameters such as flow velocity, flow rate, and pressure loss based on the internal pipe diameter and nominal diameter. This tool is designed specifically for engineers, installers and planners working with industrial and infrastructure plastic piping systems, helping them optimize pipe sizing and system performance. Whether you're planning new installations or analyzing existing ones, the calculator provides quick and reliable results to support your decision-making process.

Flow Calculator

How to Use the Pipe Flow Calculator

- Select the flow velocity and internal diameter according to the required flow rate.

- Select the appropriate SDR according to your application, this reflects the ratio of pipe diameter to wall thickness.

- Apply the below formula to find the required external diameter, ensuring compatibility with the piping specification.

- Determine the pressure loss (bar) in the straight pipe section by selecting the pipe length (m)

This calculation is vital for confirming that your pipe selection meets the capacity required for the intended flow rate and for ensuring safe and efficient operation of your piping system.

Recommended Flow Velocities Plastic Piping Systems

Choosing the proper flow velocity is crucial for optimal performance and longevity of your piping system. The appropriate flow velocity depends on the application and the location within the system:

- Suction side (pipes drawing fluid into pumps or similar equipment): Recommended flow velocity: **0.5 – 1.0 m/s** Lower velocities minimize the risk of cavitation and ensure stable pump operation.

- Pressure side (pipes carrying fluid after a pump or pressurized source): Recommended flow velocity: **1.0 – 3.0 m/s** Higher velocities are acceptable due to increased pressure, but should still be controlled to avoid noise, vibration, and excessive wear.

Maintaining these standard velocity ranges helps reduce the risk of erosion, noise, and pressure surges, while promoting system efficiency and reliability.

Formula: Correlation internal/external diameter

To find the outside diameter using the inside diameter and the applicable SDR (Standard Dimension Ratio), use the following formula:

d = di · SDR SDR - 2

Please accept all cookies to view the external content.

Where:

- d = outside diameter of the pipe

- di = inside diameter of the pipe

- SDR = Standard Dimension Ratio (a measure of pipe wall thickness)

*Enter your values below to calculate flow in any pipe size.

FAQs

How do I choose the right SDR (Standard Dimension Ratio)?

SDR is the ratio of the pipe's outer diameter to its wall thickness ($SDR = D / s$).

• Lower SDR (e.g., SDR 11): Thicker walls, higher pressure rating, but slightly reduced internal flow area.

• Higher SDR (e.g., SDR 17): Thinner walls, lower pressure rating, but larger internal flow area.

Select the SDR that matches your system's pressure requirements.

Can I use this calculator for existing piping systems?

Yes. The tool is designed for both planning new installations and analyzing existing ones. It provides reliable results to support decision-making for optimization and retrofitting.

Is this tool suitable for infrastructure projects?

Yes. The calculator is specifically designed for engineers and planners working with both industrial and infrastructure plastic piping systems.

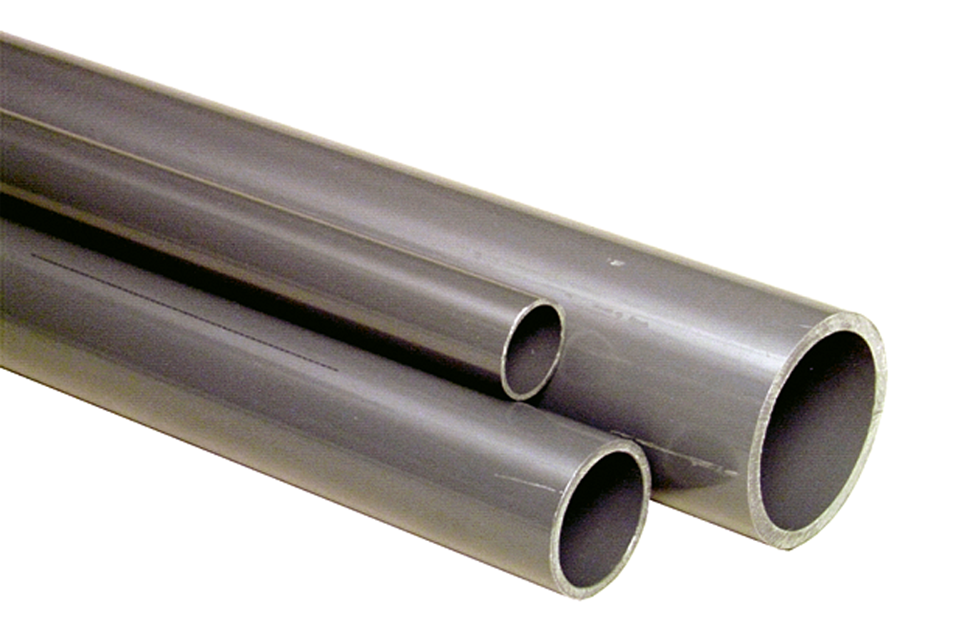

How does plastic piping compare to steel regarding flow efficiency?

Plastic piping systems generally offer superior flow characteristics due to their smooth internal surfaces. While new steel pipe has a roughness of $\approx 0.045$ mm, plastic is significantly smoother ($\approx 0.0015$ mm). This results in lower pressure loss and reduced energy consumption for pumps over the system's lifespan.