Customers only use MULTI/JOINT® within the water and gas business, right? Think again! For GF Waga, there was a customer from an unexpected quarter. It turns out none other than the Dutch army puts its trust in MULTI/JOINT® during their missions.

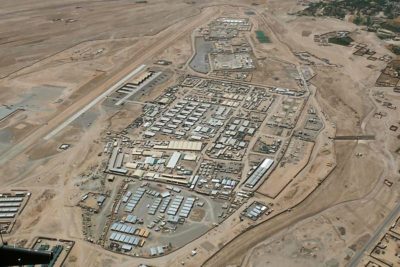

Temporary camps are the order of the day for the Dutch armed forces. Regularly the Dutch army leaps into action for humanitarian operations on a global scale. They are setting up camps in cases of (threatening) disasters like contagious diseases, floods, earthquakes, and tropical storms. The Dutch defense forces have the in-house knowledge, skills, and supplies to remove rubble, repair roads, and offer shelter to people in need. Bureau Geniewerken, the military engineers within the Dutch army, builds (water) facilities for the temporary camps. That is where the MULTI/JOINT® comes in.

A lot of these camps on missions are built from scratch, with drainage and other water pipelines constructed as temporary facilities. Time is of the essence here. An encampment needs to be ready within a few weeks to a few months. MULTI/JOINT® 3000 Plus is ideally suited for this kind of situation. In the first place because the fitting is simple and quick to install and uninstall. Amongst other things, the user-friendly bolts contribute to that. The bolts are coated with the innovative patented Lubo coating, which prevents cold welds and ensures the nuts can be loosened with great ease, even when the bolt is crooked or damaged. Special tools are not needed while installing the fitting. With the help of MULTI/JOINT® the water distribution within the camp can easily and efficiently be built up or broken down.