Securing Water Supply in Water-Scarce Areas

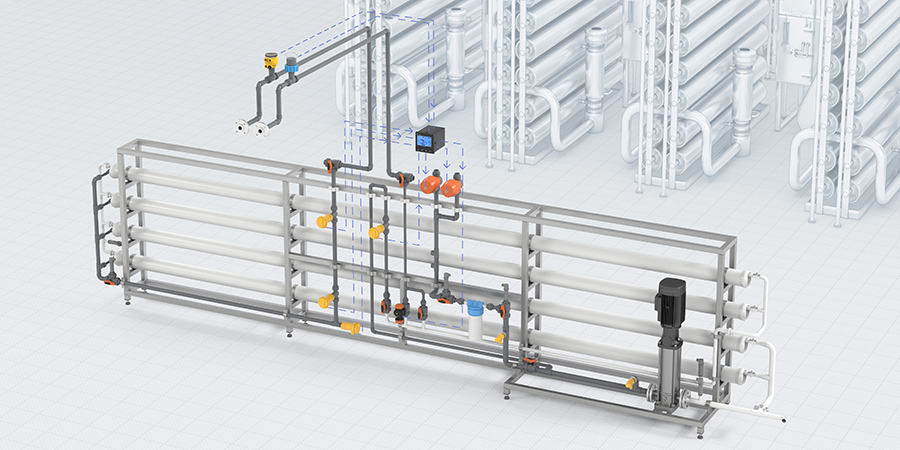

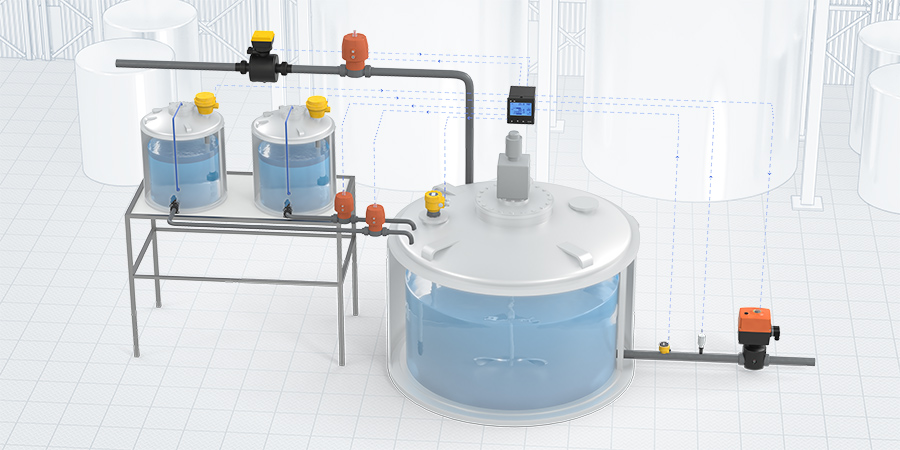

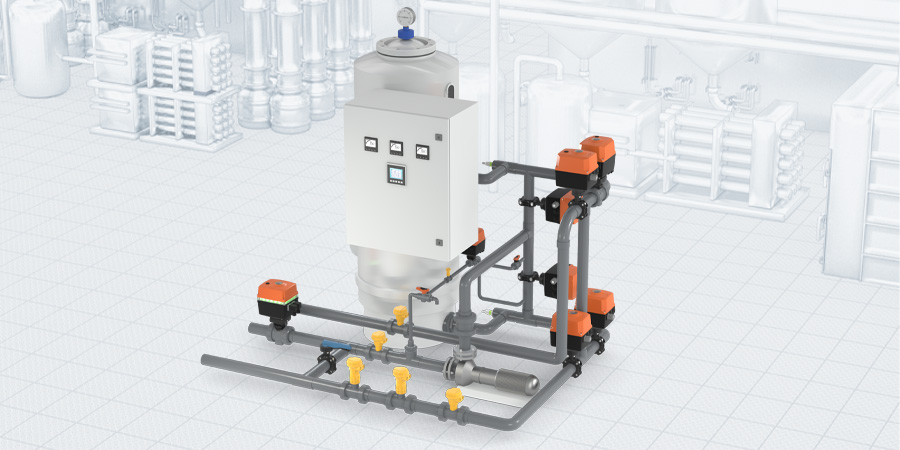

Desalination is the process of removing salt and other impurities from seawater to produce freshwater. It provides a reliable water supply in arid regions, reduces dependence on freshwater sources, and helps to ensure water security during droughts or in areas with limited freshwater resources. Corrosion-free, low-maintenance plastic piping systems, interoperable valves, and actuators are vital for the efficiency of desalination plants. Accurate measurement and control help secure operational performance, optimize water flow, and ensure a steady, cost-effective freshwater supply. These systems also ensure durability and reliability, reducing downtime and preventing leaks.