Understanding Industrial Ethernet

To enhance plant efficiency, the automation industry embraces specific trends, including Industry 4.0, implementing connected systems, adopting predictive maintenance practices, and integrating the Industrial Internet of Things (IIoT).

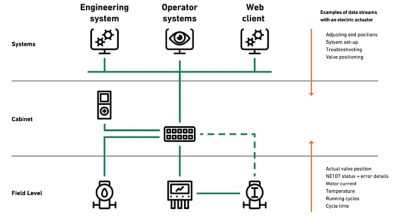

To effectively support these trends, process plants require seamless access to device data in the field, along with state-of-the-art network technology. Industrial Ethernet enables state-of-the-art technology for wired digital communication, which has been extensively utilized in various industries for many years. Different Industrial Ethernet protocols are available, depending on the capabilities of the PLCs and the specific use cases.

Upgrading outdated 4-20mA devices in industrial piping systems to state-of-the-art Industrial Ethernet technology increases operational plant efficiency and is way easier than it sounds. Whether it's a new installation or an upgrade of an existing piping system, GF can provide the right components for individual challenges. Furthermore, our in-house experts support and advise you, providing excellence in flow throughout all stages of the project.