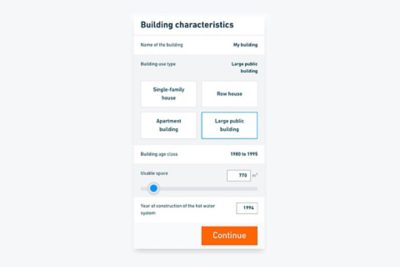

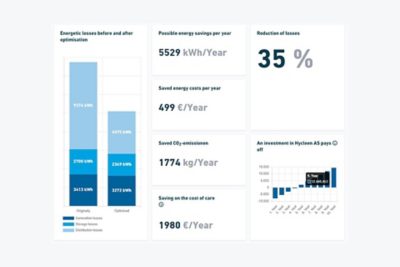

The easy-to-use online "Hot Water Energy Calculator" is the result of extensive development work by GF Piping Systems and the Ostfalia University of Applied Sciences. The calculations are based on the currently valid DIN standards and further assumptions, which are shown. A first reference project, during which the results were simulated before optimization, demonstrates that the results of the calculations are realistic. The data evaluation is being continuously refined and verified on real buildings. The tool provides valuable input for deciding when the investment to optimize a hot water system in a building will start to pay off.