Reliable pre-insulated piping solutions

With millions of meters of pre-insulated pipe installed worldwide, our systems excel in freeze prevention (often paired with our THERMOCABLE® electric tracing system) and are widely used in chilled water systems in warmer climates, as well as hot water and low-pressure steam for process and district energy applications. Designed for both buried and above-ground installations, our versatile piping solutions are ideal for extreme climate conditions, ensuring durability and efficiency across various environments.

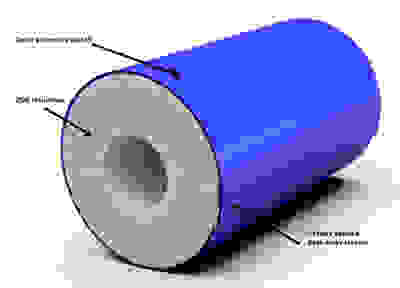

Our unique and proven polyurethane insulation process may be applied to virtually any type of core pipe and fittings up to 1200 mm (48 in) diameter and includes a variety of jacket materials with or without a channel for electric heat tracing.