Testing and Compliance

All Georg Fischer Central Plastics Meter Sets meet or exceed the following applicable standards and are subjected to an extensive testing program to ensure consistent performance in the field that is safe, robust and reliable.

- DOT Code of Federal Regulations Title 49 Part 192

- Steel Gas Carrier - ASTM A53 /API5L

- Protective Coating – SSPC / NACE

All parts are protected with sandblasted prep and an epoxy / urethane paint to meet your specifications.

- 10 - 14 mils Minimum Thickness

- ASA 49 Grey

- Cathodic Disbondement Testing per ASTM G8

- Salt Spray Testing per ASTM B117

- Impact Resistance Testing per ASTM G14

Features and Benefits

- Reduce on-site labor cost. Meter setting installs in minutes

- Fewer threaded joints reduce risk of gas leaks, increasing safety of meter setting

- State-of-the-art coating capabilities coupled with the industry leading corrosion protection

- Can be coupled with support brackets or pipe stands

- 100% Pressure Testing to ensure products are leak free

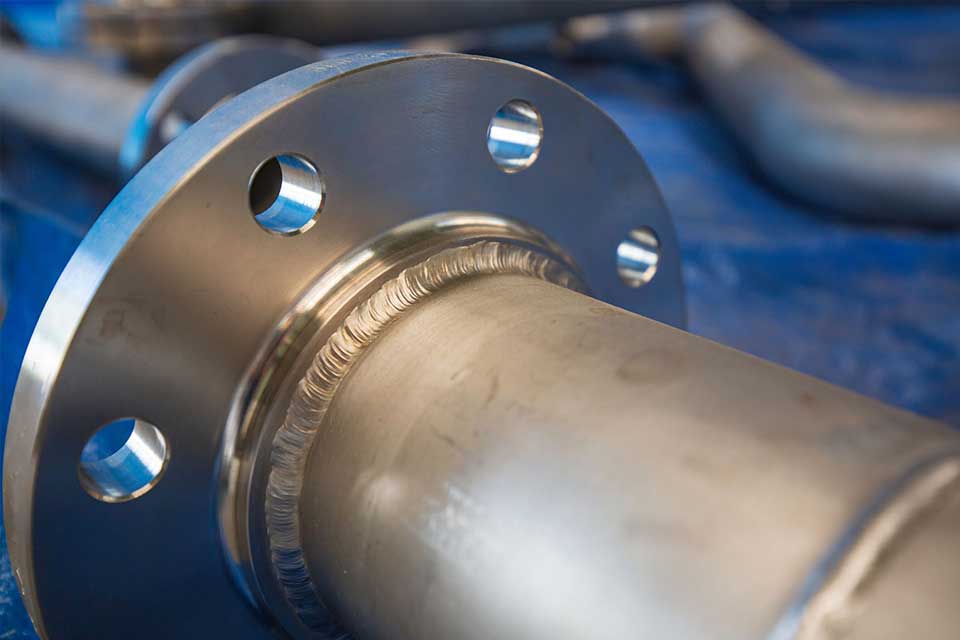

- API 1104 Certified Welding

- Packaging and shipping based on the customers’ needs

- Full Traceability (heat/lot numbers, rating/grade, serial numbers and MTRs)

- Weld Mapping and Inspection Package (weld, test, blast profile, paint DFT with instrument cert)

- Product Serialized for GIS/Compliance needs (replacement packages accessible at any time)

- Certified Welding Inspector and API 1104 qualified welders on staff

Commercial Product Offering:

- Rotary Meter Sets

- Multi Meter Drops (manifolds)

- Farm Taps

- District Regulator Stations

- Meter Replacement Spools

- Specialized Projects and Design Upgrades