We offer our customers a modern and application-oriented training environment that considers all the specific requirements regarding the content and the structure of the training. Always focusing on practice and experience with our systems and solutions, we do not only provide theoretical instructions and manuals, but instead focusing on what is necessary regarding the correct and safe handling of our products, systems and solutions. New to the world of plastics? Not to worry, our courses are designed specifically to help installers become experts in the application of plastic piping systems – to help to achieve the highest, most reliable quality and service on the market.

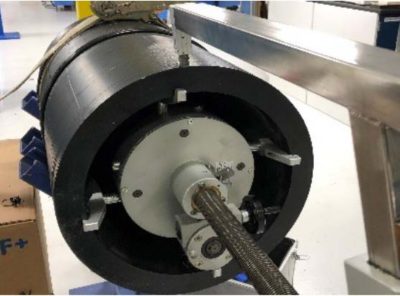

Clearly designed and structured training courses ensure that participants with varying levels of experience receive the knowledge transfer required to maintain the highest installation standards and quality. This course covers electrofusion installation for sizes 14 IPS and up.