We make Process Automation easy

At GF Industry and Infrastructure Flow Solutions, we provide comprehensive solutions for your processes, focusing strongly on manual and actuated valve, and measurement solutions such as flow, pH/ORP, conductivity, temperature, pressure, level, dissolved oxygen (DO), free chlorine as well as monitors, transmitters and controllers for the safe management of your liquid processess.

We specialize in designing, manufacturing, and supporting to meet customer needs globally. We have expertise in pipes, fittings, jointing technologies, manual and actuated valve and measurement solutions for water/wastewater and corrosive media throughout various industries.

Water Treatment

Ekopak creates "water as a service" containers to recycle and revalue water. Their containers are important for processing water in production as well as for drinking water in consumers' homes.

Please accept all cookies to view the youtube video content.

Lithium Recovery

The Canadian company Saltworks Technologies Inc. specializes in industrial wastewater treatment. Thanks to modern skids, it is capable of extracting valuable raw materials from used process water, resulting in a sustainable source of lithium, nickel, and cobalt.

Please accept all cookies to view the youtube video content.

Chemical Processes

Caramba Bremen GmbH specializes in chemical solutions with a focus on industrial applications and vehicle cleaning. During production, the company uses 18 raw materials from storage tanks to create a total of 800 different products. Eight million kilograms are mixed and dosed every year.

Please accept all cookies to view the youtube video content.

Innovation with purpose

Our global team of Process Automation Experts continuously develops new solutions to make Process Automation as easy and sustainable as possible - even in challenging applications. Discover our latest innovation here.

Enhancing plant efficiency with digital field connectivity

To enhance plant efficiency, the automation industry is embracing specific trends. These trends include Industry 4.0, implementing connected systems, adopting predictive maintenance practices, and integrating the Industrial Internet of Things (IIoT).

Our Industrial Ethernet connectivity options help to plan flexible networks and commission the devices quickly and easily, including access to all relevant device parameters.

GF Industry and Infrastructure Flow Solutions offers Industrial Ethernet for both Electric Actuators and Electro-pneumatic Positioners.

?qlt=82&ts=1717408621508&dpr=off)

Our Commitment and Expertise

Decentralized Solutions

In this session, innovative world leaders and GF Industry and Infrastructure Flow Solutions experts discuss how decentralized soutions and the concept of water as a service is a concrete answer to the problem of water scarcity and access to clean drinking water.

Please accept all cookies to view the youtube video content.

Water Transportation

In this session, our experts discuss how the water industry is changing, which are the challenges in front of us and how GF Industry and Infrastructure Flow Solutions is preparing to tackle them.

Please accept all cookies to view the youtube video content.

Future WT Plants

In this webinar, our experts and customers discuss how the role of automation in increasing efficiency and reducing wastage in water treatment plants is becoming more pivotal now and in the future.

Please accept all cookies to view the youtube video content.

Discover the product range

We offer the full package of solutions, that allow you to build highly energy efficient and reliable processes. Discover our Valve Solutions and our Measurement Solutions.

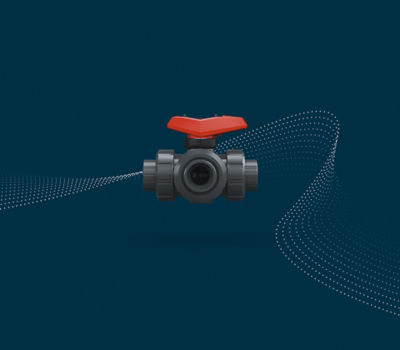

Valves Solutions

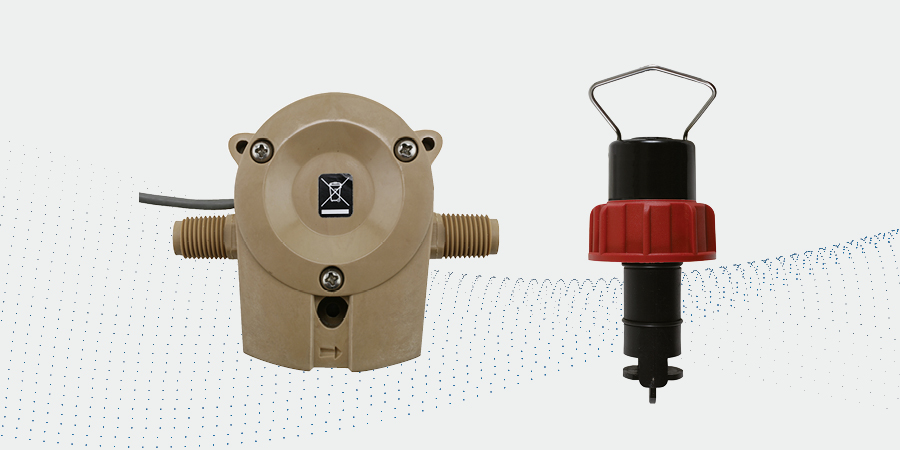

Measurement Solutions

Support during each Project Phase

We have additional resources and services ready to support you during each project phase, from idea to execution.

FAQs

What are the reasons and possible mitigations for early wear and tear of the valve used in water treatment applications?

Early wear and tear of valves can occur for various reasons. Proper handling and regular valve maintenance are essential for maximum service life. Plastic valves in water treatment applications can experience early wear due to chemical exposure, high pressure, and abrasion from particulates. Chemical corrosion weakens the material, while pressure fluctuations stress the valve. Particles in the water can abrade surfaces, exacerbating wear. Valve material selection is essential to mitigate this. Implementing pressure regulation systems and filters can reduce stress and particle ingress. Regular maintenance, such as cleaning and lubrication, helps extend valve lifespan. Additionally, alternative valve designs or coatings may offer increased durability in harsh operating conditions. It is also essential to execute a proper installation. The valve must be installed in the piping system so that the system does not apply any additional stress on the valve, which can hurt the valve operation. Our Planning Fundamentals have a detailed guide for correct dimensioning and valve installations based on operating conditions on page 21 to 24 in our edition "Valves and Actuators". In addition, GF Industry and Infrastructure Flow Solutions is offering online free-of-charge tools like the “Flange Connection Tool”, “Chemical Resistance Tool” and “Valve Dimensioning Tool” to help with the right choice.

What are popular technologies in flow measurement?

- Velocity-based flow measurement technologies

All of the flow sensors produced by GF belong to the broad category of velocity-based flow measurement devices. This vast offering includes paddlewheel, electromagnetic, in-line rotor, and turbine flow sensors. Principles of operation vary considerably for each type, but some very important installation considerations are standard throughout.

- Fully Developed Turbulent Flow

Velocity-based flow sensors depend on fully developed turbulent flow for accurate and repeatable measurements. Fully developed turbulent flow occurs in Newtonian fluids with a Reynolds Number (Re) greater than 4,500. Low flow rates, viscous liquids, and large pipe sizes make fully developed turbulent flow more difficult to achieve. The opposite is also true. That is, for a given set of conditions, simply reducing the pipe size to increase the local flowvelocity will produce a higher Reynolds Number.

- Electromagnetic flow sensors

Electromagnetic flow sensors, like types 2551 and 2552, operate on Faraday’s principle of electromagnetic induction, and have no moving parts. As fluid (must be conductive >20 μS) moves through the magnetic field produced at the sensor tip, a voltage occurs that is directly proportional to the fluid velocity. Internal electronics then convert this voltage into a frequency and/or a 4 to 20 mA output. GF electromagnetic flow sensors are insertion-style, suitable for use in a wide range of pipe sizes.

- Paddlewheel flow sensors

Paddlewheel flow sensors are insertion devices mounted perpendicular to the piping system and rely upon the energy in the flow stream to spin a rotor (paddlewheel) around a stationary shaft. Most paddlewheel flow sensors utilize rotors with magnets embedded in each blade.

The magnets are typically used either in conjunction with a coil internal to the sensor housing to produce a sinusoidal output (self-generating, non-powered sensors), or to trigger an internal electronic switch to produce a square-wave output (transistor-type, powered sensors). Either way, the resulting frequency is directly proportional to the fluid velocity.

In our Planning Fundamentals, we have a general selection guideline to help the user choose the appropriate sensor type to obtain optimal flow measurement results.

Read more on page 139 to 141 of "Valves and Actuators".

What are the trends in digital communication technologies?

Digital communication in process plants becomes increasingly important due to automation trends around digitalization and Industry 4.0 which can't be supported by traditional 4-20mA analogue technology.

In the past decades, different standard organizations specified several digital communication technologies. End customers in the process industries can freely choose the technology that best fits their needs. Digital communication technologies open up the potential for the highest plant efficiency.

There is no need for expensive I/O cards and extensive device wiring, as only one cable goes from the PLC to the field level. Flexible topology concepts support the individual needs of a process plant.

Smart field instruments share their valuable data to enable continuous process improvement. The field of potential improvements ranges from diagnostic insights to simplified troubleshooting to extensive trend monitoring to optimize processes or avoid unplanned plant shutdowns.

Wireless communications between field devices and mobile applications complete the picture of a highly efficient process plant by providing a simple possibility to connect to a device for live device data or parameterization.

Industrial Ethernet technology with protocols like PROFINET, EtherNet/IP or Modbus TCP is best suited to fully support the trends around digitalization, as Ethernet technology is already the standard communication technology on the upper layers of the automation pyramid. By bringing Ethernet down to the field level, systems have seamless data access to a single sensor or actuator with fewer hardware components and without protocol conversion. Global market studies show that the share of Industrial Ethernet compared to traditional field level technologies increased a lot and further will increase in future. GF Industry and Infrastructure Flow Solutions supports the most critical digital communication technologies in the process automation portfolio for both sensors and actuators.

Sign up for our newsletter

Don't want to miss what's new for process automation? With our quarterly newsletter we keep you up to date! Please enter your contact information below so we can add you to our mailing list.

Please accept all cookies to view the external content.