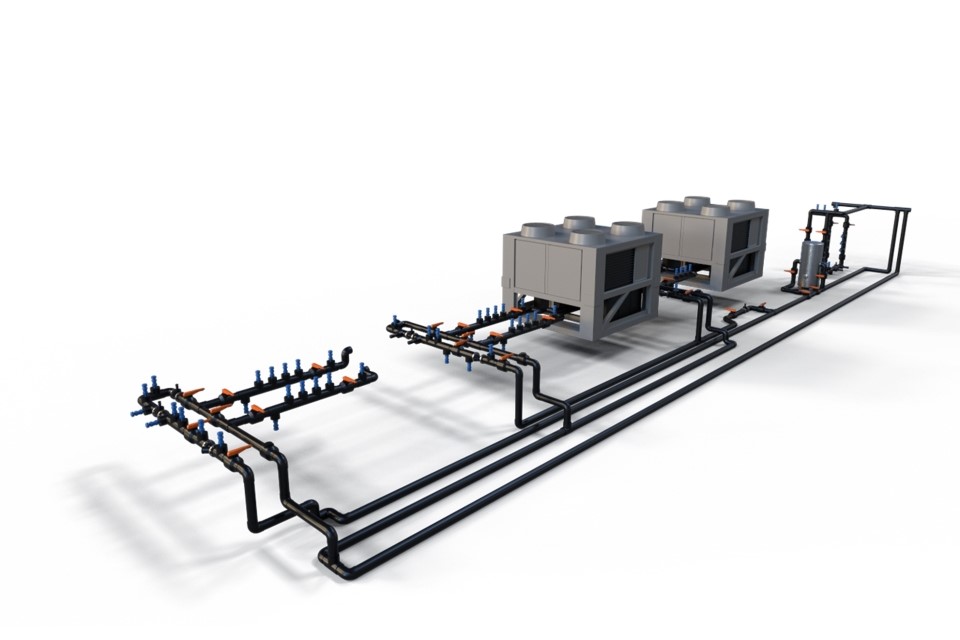

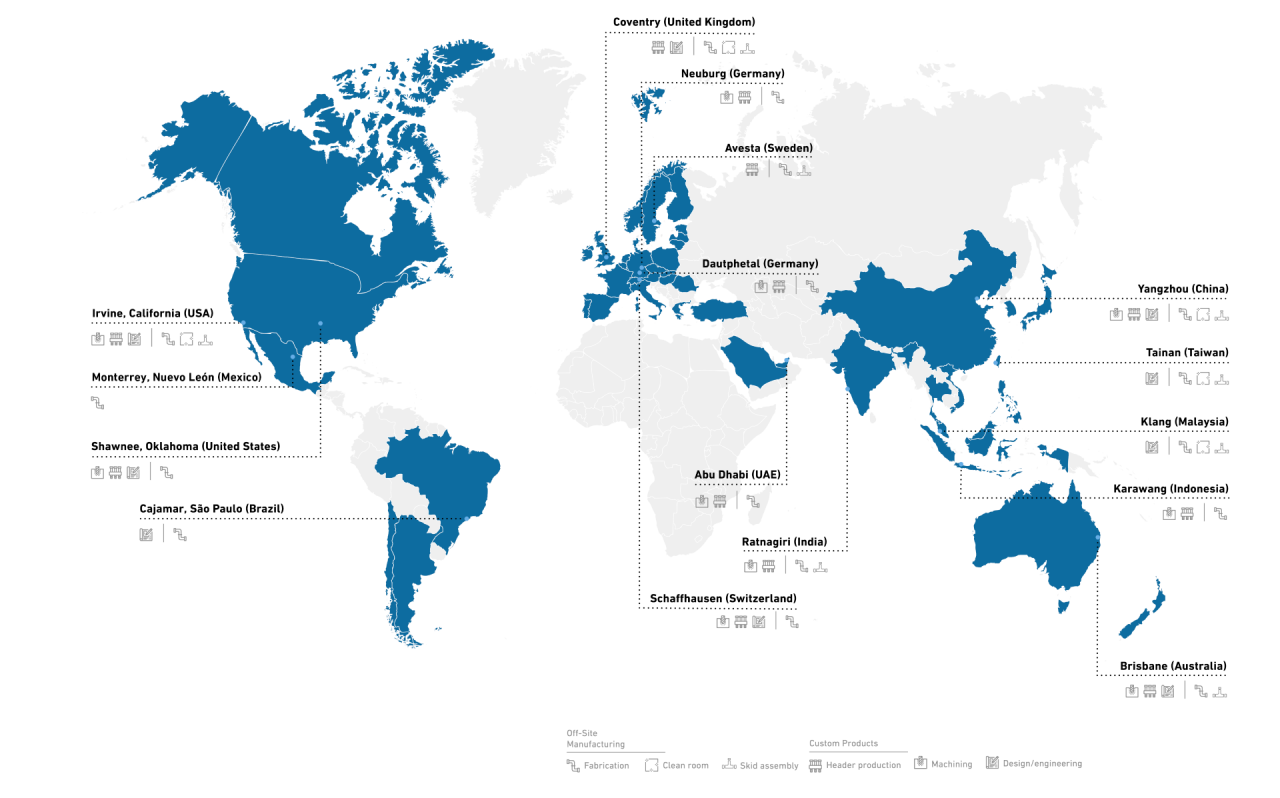

Located in Brisbane Queensland since 2020 and ISO9001 certified for fabrication of plastic piping systems, our state-of-the-art prefab centre brings GF fabrication capabilities to the next level of excellence.

Take advantage of our experts and their extensive range of specialised plastic fabrication equipment for customised solutions, tailor-made for your specifications.

To fabricate as much as possible in a controlled environment will reduce the scope of on-site works, minimise site risk, improve fabrication quality and shorten project delivery time. Whether the project is small or big, GF Australia ensures our support throughout all stages of your project, on-site and off-site, transforming your ideas and concepts to life.

Fabrication Capabilities

| Welding Type | Dimensions | Materials |

| Electrofusion | 20mm - 2000mm | HDPE |

| Butt Fusion | 63mm - 1200mm | HDPE, PP |

| IR (Infrared) | 20mm - 225mm | HDPE, PP, PVDF, ECTFE, PVC-U metric (20-63mm) |

| Saddle | All GF sizes available upon request | HDPE, PP, PVDF, ECTFE |

| Extrusion | All GF sizes available upon request | HDPE, PP, PVC-U, PVC-C |

| Bonding and Cementing | All GF sizes available upon request | PVC-U, PVC-C, Nylon |

| Mechanical | All GF sizes available upon request | MULTI/JOINT® |

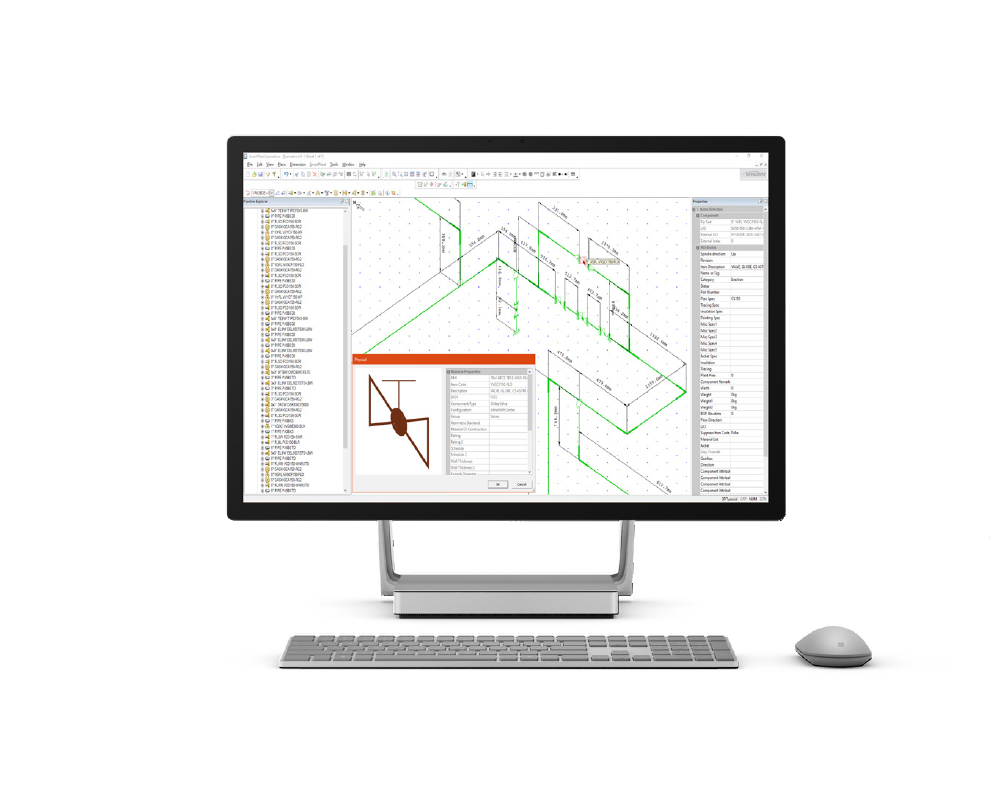

Engineering and Design Services

By integrating engineering as the first step to prefabrication, GF minimises errors, improves efficiency, and simplifies installation.

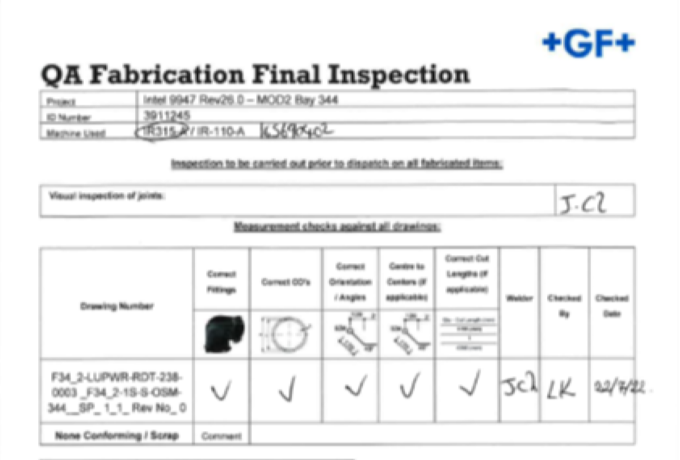

Quality Assurance

With 100% end-to-end QA and QC, GF follows global process standards in engineering, quoting, machining, and training, continuously enhancing performance through regular internal audits.