Redefine Tomorrow

In an era where precision and efficiency dictate industrial success, the IR-225 M emerges as a beacon of technological evolution. As pioneers in infrared fusion technology for over three decades, we are proud to unveil a product that is designed to redefine the boundaries of infrared fusion.

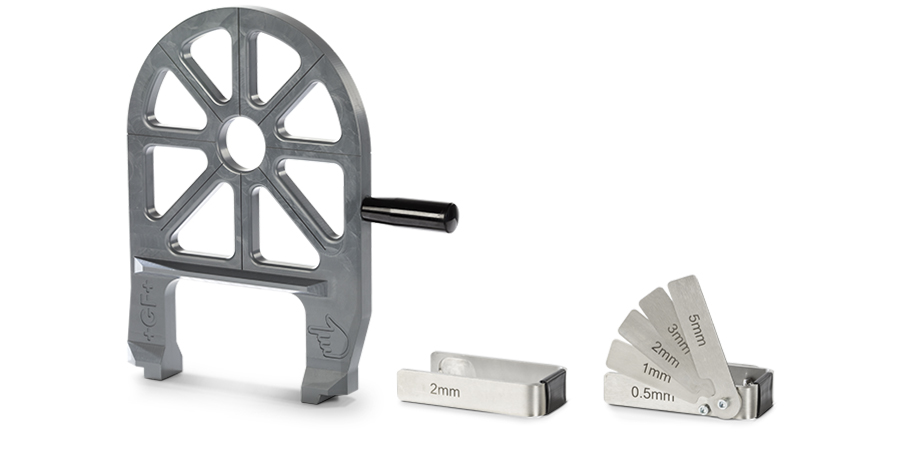

Building on our 30+ history as the pioneers of infrared fusion manufacturing, the IR-225 M seamlessly merges the trusted functionalities of IR welding technologies with innovative features, driving forward to make jointing faster, easier, and more reliable.