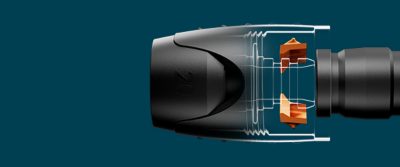

When drinking water installations or cooling water systems need to function in a safe, clean and sterile manner, GF JRG has the solution. Founded in 1887 (and part of GF since 2008), the company bundles its expertise in building technology in the Georg Fischer world of fluidics with the Sanipex classic, Sanipex MT, iFIT and INSTAFLEX piping systems, connectors without dead space or flow-optimized fittings, as well as the Hycleen Automation System.

Please accept all cookies to view the youtube video content.

What we do at the site

As a manufacturer of fittings for domestic water installations, we have our own foundry and state-of-the-art CNC-controlled casting and décolletage machines.

Administrative and technical planning operations (AVORs) support our production departments, control the technological and economic processes and ensure proper documentation.

Foundry

The foundry is where high-grade parts are produced from Cu alloys on a fully automated molding line.

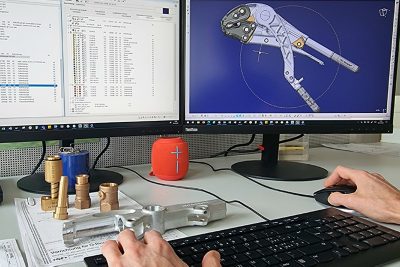

In close cooperation with the Foundry Engineering Center, the components are engineered on the CAD system, and filling and solidification processes are simulated on the computer. The milling program for the pattern equipment is created using CAM.

AVOR

In close cooperation with the production planning department, entire molding devices and milling programs are created on Catia CAD systems and electronically transferred to the departments concerned for further processing.

- Design of required equipment and programming of machine tools (Catia CAD)

- CNC programming

Décolletage

This part of the production process turns parts on single and multi-spindle automatic lathes for internal and external customers.

Machining

We produce the parts from castings and block or slug material for internal and external customers using machining.The high productivity transfer machines are loaded and unloaded by robots.

Assembly

With cutting-edge machines, some equipped with robots, all water-bearing castings are put through a 100% leak test in the assembly department.

And in the final assembly, the modern plants are equipped with automatic monitoring cameras to guarantee high quality.

The components are packed and transferred to the high-bay warehouse to complete the process.

Toolmaking

Toolmaking comprises mechanical engineering, grinding/wire erosion, and pattern-making teams. Within GF JRG AG, this service department makes all manufacturing and production equipment for the foundry, assembly, and machining departments. Including the following facilities and components:

- Pattern plates and core boxes -> Foundry

- Accessories for the fully-automated sawing, fettling, and punching cells -> Fettling shop

- Chucks and machining tools such as jaws, countersinks, and facing slides -> Casting

- Machining tools such as forming and grooving plates, multi-sided cutters -> Décolletage

- Special tools, assembly aids -> Assembly

And all production equipment is maintained, repaired, and serviced in the tool shop.

Maintenance

Maintenance staff maintains and repairs production equipment to guarantee the highest possible plant availability. In addition, they work with plant managers to find solutions to prevent recurring faults and, consequently, continuously improve plant availability.

Maintenance also involves retaining the value of the building infrastructure as a whole, building cleaning, the green spaces, and the building grounds.