The PVC-U system from GF Industry and Infrastructure Flow Solutions offers maximum safety and reliability for countless applications, from drinking water to highly aggressive chemicals. The best possible piping components are also available for special requirements. Although the PVC-U system has been around for decades, we continue to invest in this product to become more innovative and more sustainable.

Please accept all cookies to view the youtube video content.

Bio PVC-U

As the first manufacturer of pressure piping, GF Industry and Infrastructure Flow Solutions is introducing bio-attributed materials to all of its market-leading polyvinyl chloride (PVC) metric pressure pipes produced in Europe. The greener PVC resin, made using tall oil, a waste product from paper production will see a reduction of up to 90% in the CO2 produced versus standard PVC while still maintaining the highest quality, durability, and recyclability.

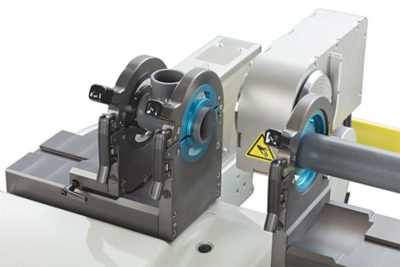

IR PVC-U

GF Industry and Infrastructure Flow Solutions has been producing PVC-U for more than 65 years and is also a leader in infrared welding technology. Now we have combined our expertise in these two fields to bring the first IR welded PVC-U system to the market.

Jointing Technologies

Cementing is a simple and quick method of jointing that creates a secure, leak-proof joint with little expertise or expensive equipment required. Cementing is recommended when a strong, durable joint is essential and time is of the essence. Designed specifically for use in plastic piping systems, both solvent cements and solvent-free cements create a solid bond between two pipe elements, resulting in a joint that can withstand movement and bending with ease.