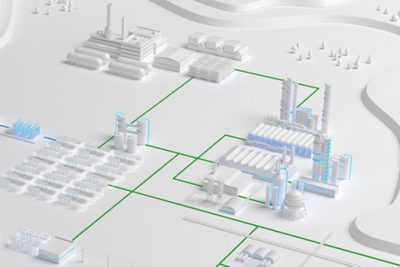

Certified systems powering hydrogen distribution

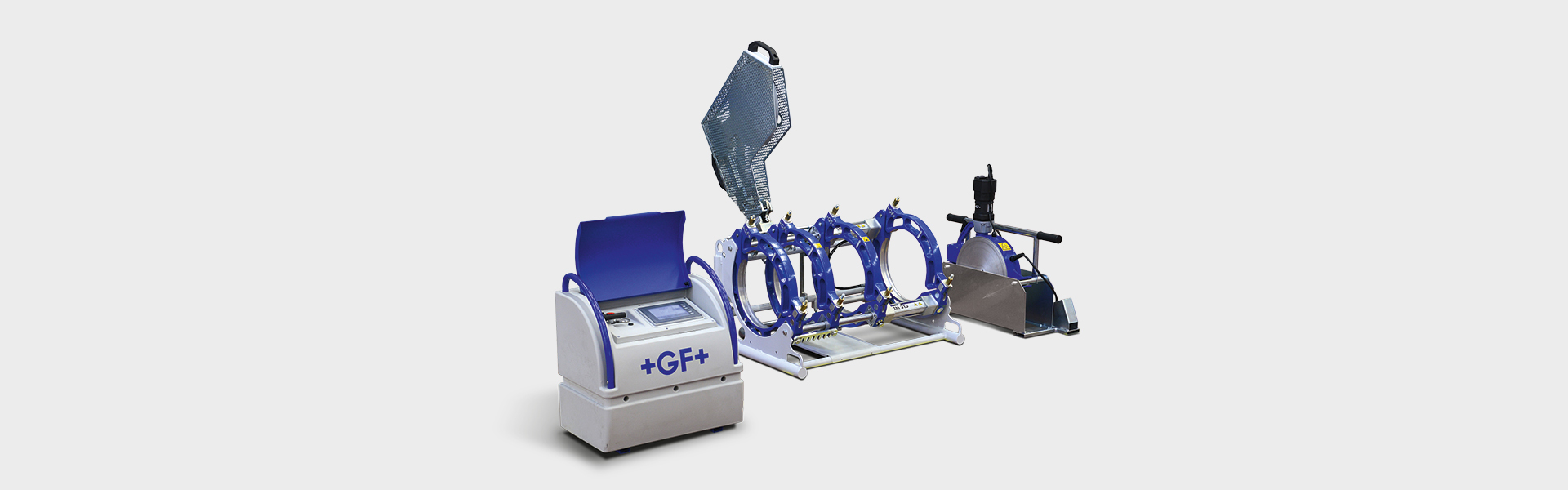

Hydrogen transportation is largely facilitated via big pipelines in combination with other energy carriers such as ammonia and Liquid Organic Hydrogen Carriers (LOHC). The repurposing of natural gas pipelines for hydrogen transportation faces some technical challenges, such as hydrogen embrittlement and permeation. Our polymer utility products have been certified “hydrogen ready” for low-pressure distribution applications, according to the requirements and regulations of our customers.